Whenyou’re searching forsteel shredders for sale, there’s a lot more to consider than just price. Whether you’re running a scrap yard, recycling plant, auto dismantling facility, or metal scrap processing line, choosing the right shredder can make a huge difference in operational efficiency, throughput, maintenance costs, and long-term return on investment. Below are the key product knowledge areas and technical parameters that every buyer should examine carefully when evaluating scrap metal shredder machines.

1. Throughput and shredding capacity

One of the first questions to ask is:How much scrap metal can the shredder process per hour or per day? Throughput is usually expressed in tons per hour (tph) or kg/hour. A shredder that can only handle light or thin metal scrap at low volumes may not be sufficient for heavy industrial scrap or automotive scrap. Meanwhile, a high-capacityindustrial shredder for metal might cost more upfront but deliver far better performance over time.

ENERPAT offers a variety of shredders tailored to different volume needs. For example, the MSC-E series four-shaft shredder can handle up to 1–20 tons per hour depending on configuration.

On the other hand, ENERPAT’s MSA-F single shaft shredders are often used in lower-volume but more controlled applications, with output rates ranging from a few hundred kilograms per hour up to several tons.

When comparingsteel shredders for sale, match the throughput to your expected scrap input volume—and allow for future expansion.

2. Shredder type: single-shaft, dual-shaft, four-shaft, hammer mill, etc.

Not all shredders are built the same. The shredding mechanism—single shaft, two shafts, four shafts, hammer mill, etc.—dramatically affects what materials the machine can handle, how uniformly the metal is shredded, and how easy it is to maintain.

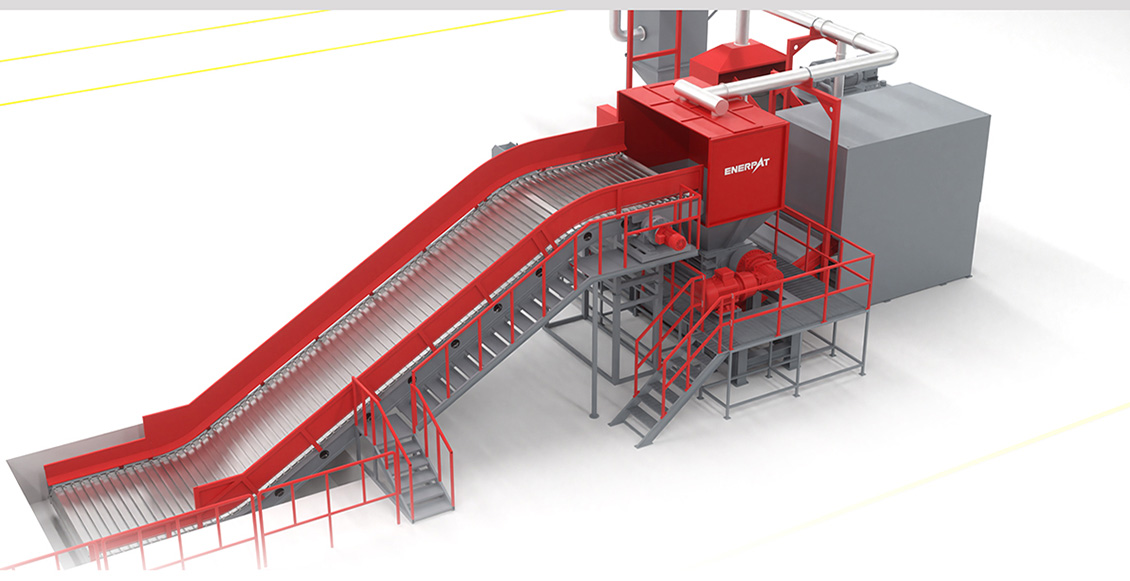

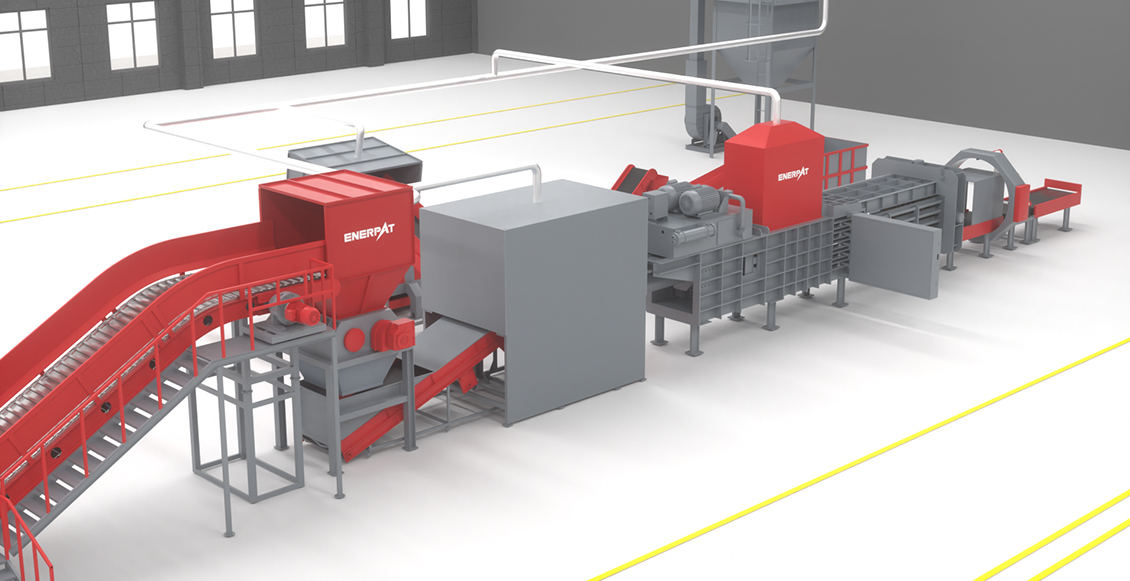

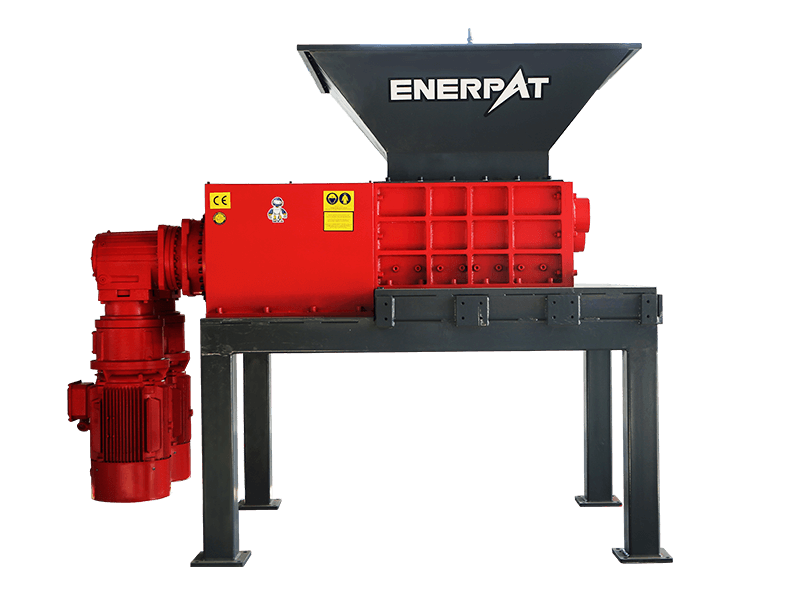

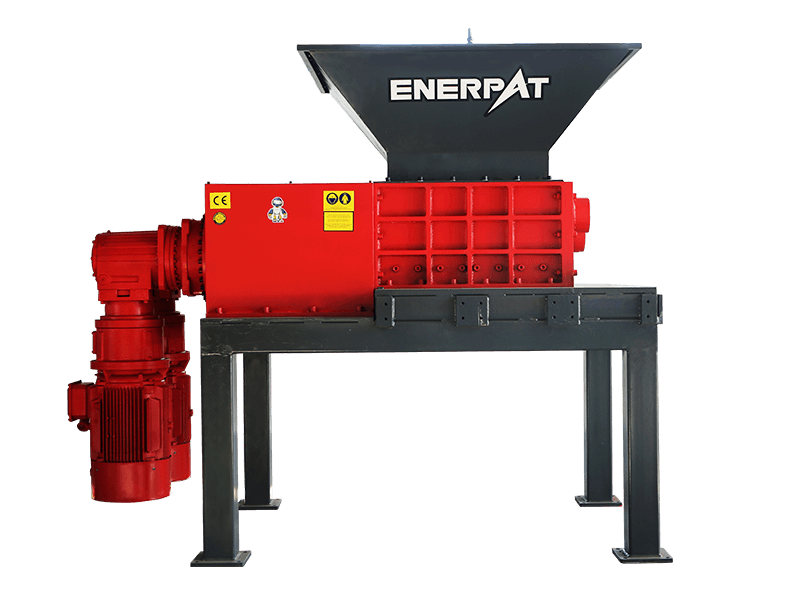

Single shaft shreddersare typically good for controlled input, uniform output sizing, and are suitable for shredding metal sheets, cables, and containers when followed by downstream separation equipment. ENERPAT’s MSA-F single shaft models, for instance, are designed for stability and uniform output particle size.

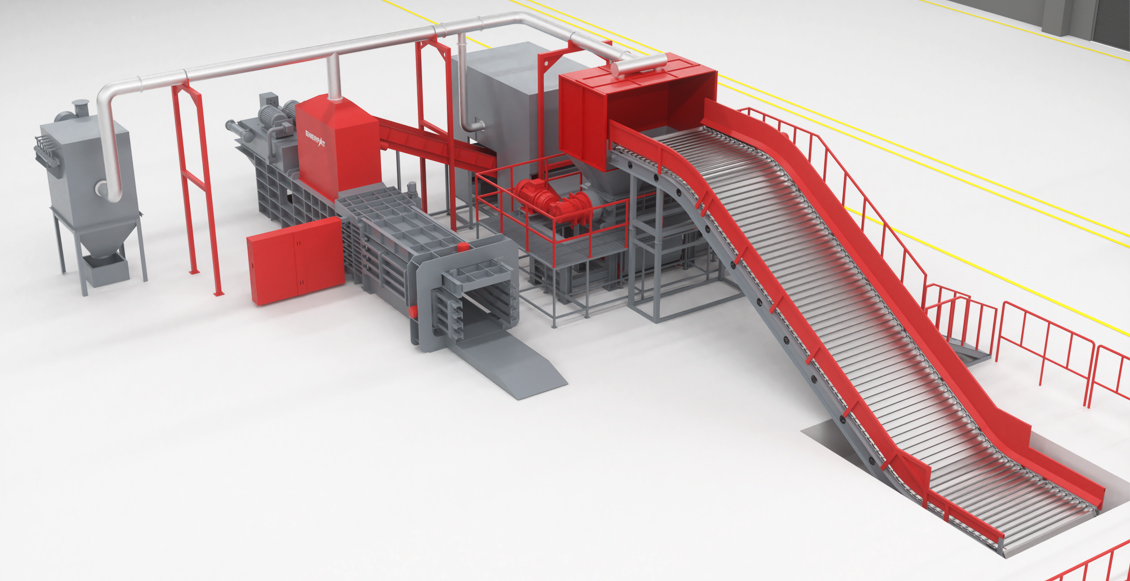

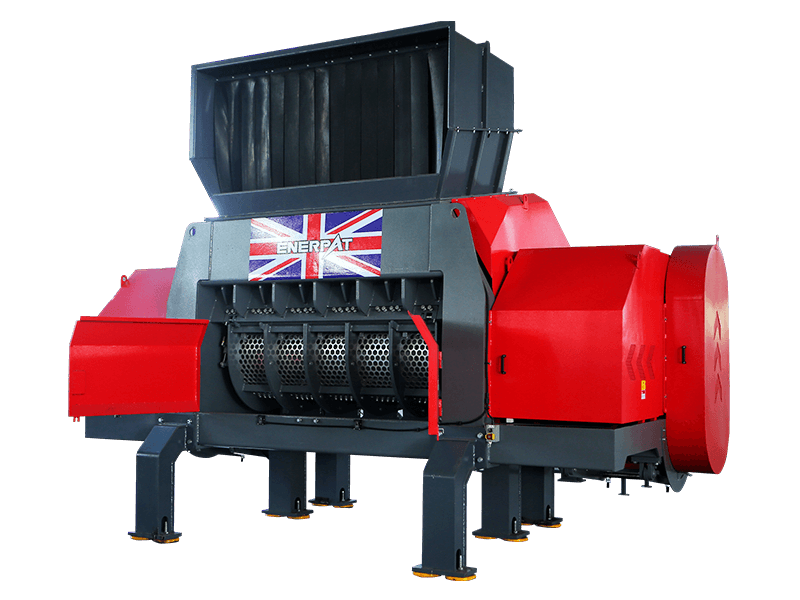

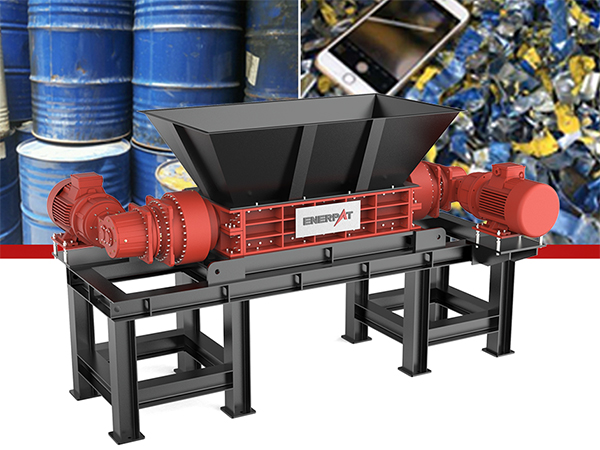

Two shaft (dual shaft) shredders offer stronger tearing and shearing action, and are better suited to bulky scrap materials or mixed waste streams. ENERPAT’s MSB-E series of two-shaft shredders are built precisely for bulky waste, scrap metal drums, and car shell materials.

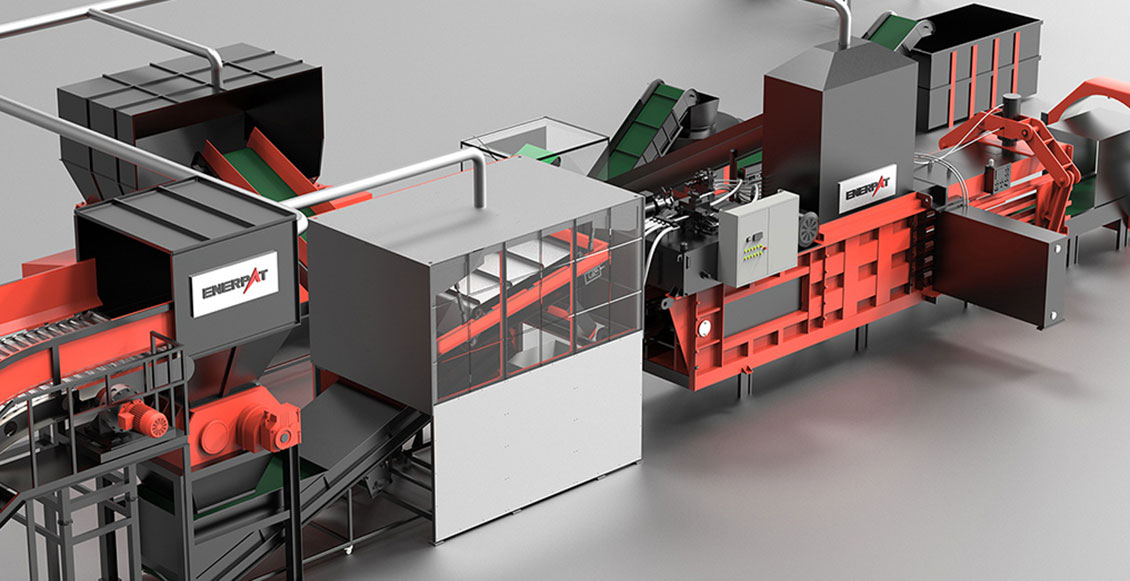

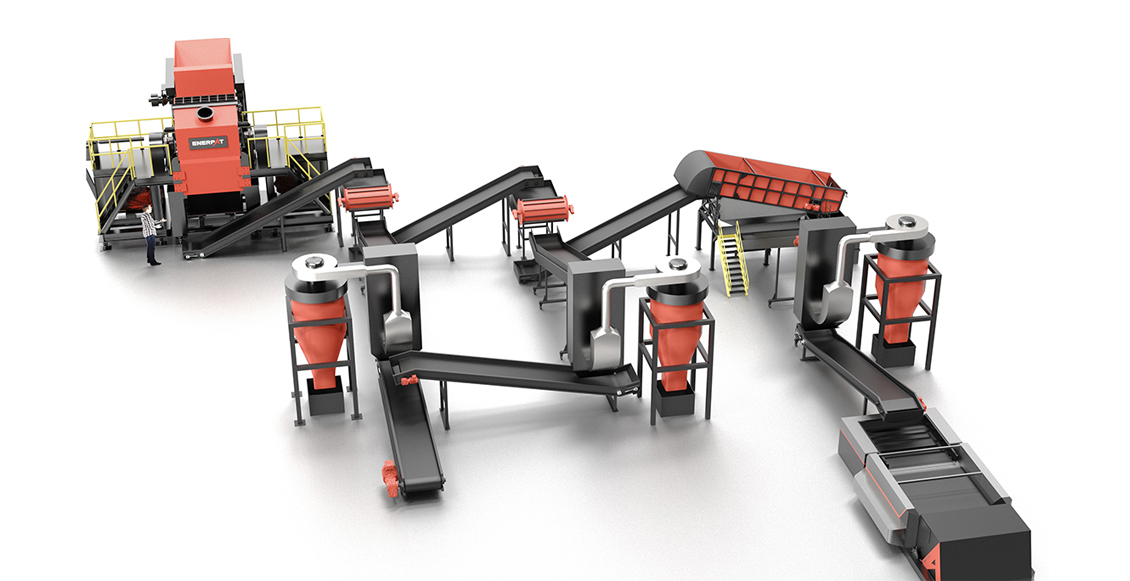

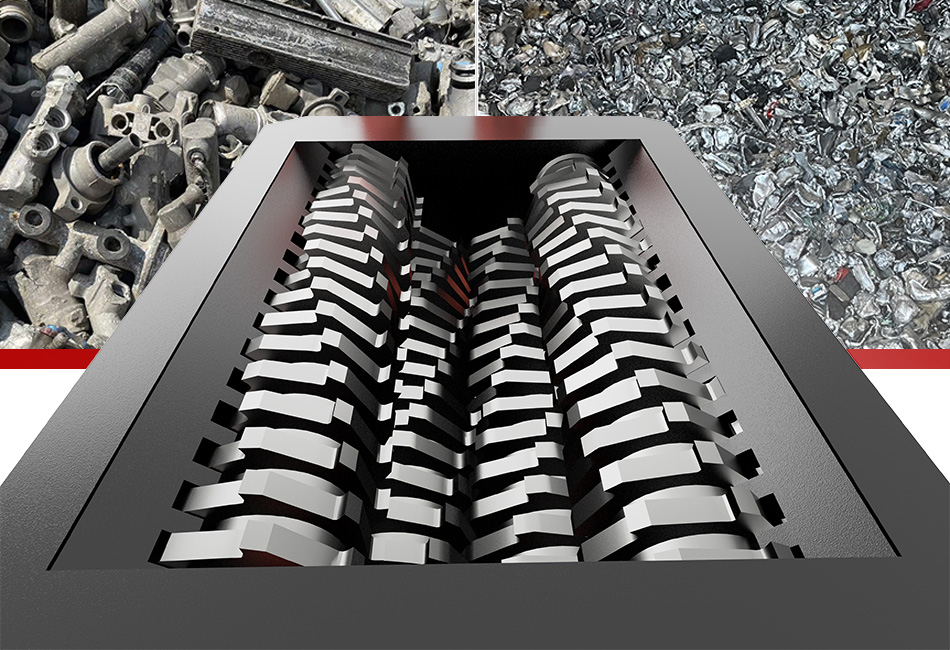

Four shaft (quad shaft) shredders like ENERPAT’s MSC-E series provide enhanced shearing, tearing, and cutting, giving higher shredding efficiency and better control over output particle size. These are particularly useful for metal shredding where downstream sorting or refined particle sizing is required.

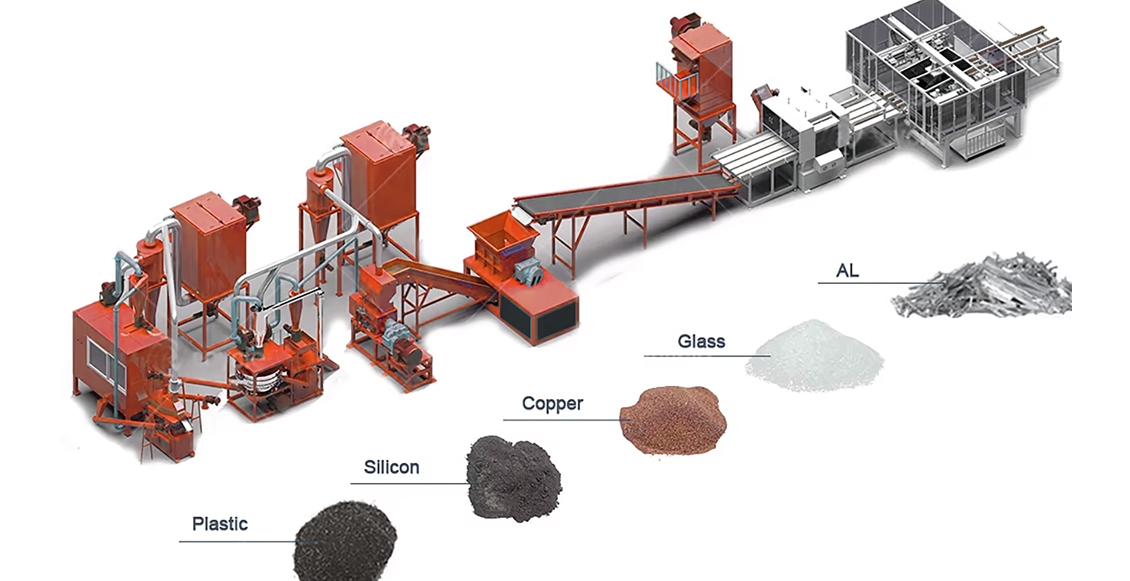

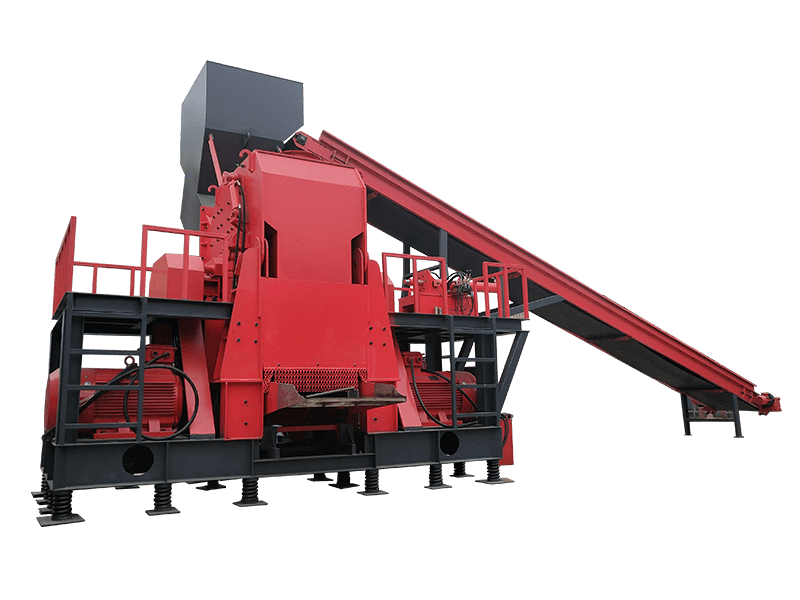

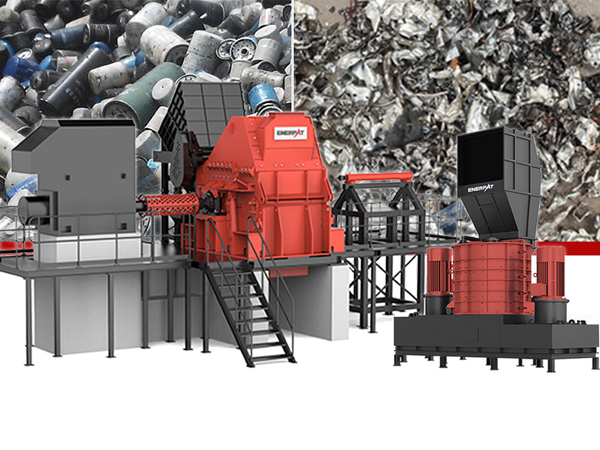

Hammer mills are another option, especially when the goal is to reduce engine blocks, motors, steel wheels, or other bulky metal scrap into smaller fragments suitable for separation or further processing.

Choosing the right shredding design depends on the specific scrap metal types you will process, desired final particle size, downstream separation equipment, and whether you plan to recycle or sell shredded metal directly.

3. Build quality, blade materials, and wear resistance

When buying steel shredders for sale, it’s essential to evaluate build robustness, blade quality, knife materials, and maintenance considerations—these factors directly impact downtime, operational life, and operating costs.

ENERPAT machines often use high-strengthalloy or NiCrMo steel blades that are heat-treated for enhanced wear resistance.

Blade thickness, hardness, and the ability to re-sharpen or flip blades can extend service life. On ENERPAT’s documentation for single shaft shredders, blades made of heat-treated DC53 steel are described as being rotatable or flipped to use multiple edges before replacement, which helps reduce maintenance costs.

Heavy-duty gearboxes, hardened frames, and modular designs are also critical. ENERPAT’s shredder boxes are constructed with mortise-and-tenon welded plates for durability and ease of maintenance.

Ensure that anyscrap metal shredder machine you consider can handle abrasive or contaminated metal scrap, and that spare parts (blades, bearings, screens) are readily available.

4. Control systems, safety, and maintenance features

Advanced control systems and safety features are a critical differentiator among steel shredders for sale. A machine with better monitoring, overload protection, and ease of maintenance will save downtime, repair costs, and safety risks.

ENERPAT shredders includePLC-controlled automatic systems that monitor the shredder’s operation, automatically reverse blades on overload, and shut down when material is jammed or runs out.

Safety interlocks, access door switches, and modular component design make maintenance safer and more efficient.

Dust control, vibration dampening, and noise suppression are also important, especially in metal shredding. ENERPAT emphasizes low noise and low vibration designs in its industrial shredder for metal machines, which contributes to more stable operations and better operator safety.

When purchasingsteel shredders for sale, verify that maintenance, blade replacement, cleaning, and troubleshooting are straightforward—and that safety features are built into the machine, not just added on.

5. Energy consumption, operational costs, and ROI

A common mistake is to focus only on the upfront cost of a shredder, without considering how much energy it will consume, how often it will require blade replacements or maintenance, and how much downtime may reduce productivity. All these factors affect the real cost-per-ton of shredded steel scrap.

ENERPAT machines are engineered forlow energy consumption and efficient operation. According to ENERPAT, their industrial shredder for metal designs feature optimized hydraulic feeding and rotor designs to reduce power draw and improve shredding efficiency.

Maintenance costs—including blade sharpening, screen changes, bearing replacements, and gearbox servicing—vary by design. Choosing a shredder with replaceable or reversible blades, easy screen access, and modular parts can reduce long-term costs. ENERPAT’s modular design philosophy helps simplify maintenance and reduce downtime.

When evaluating steel shredders for sale, request or calculate the expected cost per ton of shredded output, factoring in electricity, blade wear, labor, maintenance, and downtime. The lowest purchase price may not translate to the lowest operational cost or best return on investment.

6. Supplier reputation, spare parts availability, and after-sale support

Even the best scrap shredding equipment can suffer if service, spare parts, and technical support are lacking. When buying steel shredders for sale, understanding the supplier’s reputation, parts logistics, and after-sales service is essential.

ENERPAT Scrap Steel Shredder Manufacturer is a global player with decades of experience in waste shredding and recycling equipment. As stated on ENERPAT’s website, they operate in over 165 countries and emphasize a strong support network.

Availability of replacement blades, screens, hydraulic parts, and electrical components is crucial—especially for industrial shredder for metal machines operating under heavy load. Suppliers who maintain spare parts inventories or offer refurbishment services can save significant operational downtime.

Warranty terms, shipping logistics, and local support are often overlooked but should be clarified before purchase. ENERPAT provides global shipping and after-sales services, which is a major advantage when buying shredders for international scrap recycling operations.

In many practical recycling applications, ENERPAT’s shredders can match or exceed the performance of competing lindner shredder models, especially when factoring in long-term durability, operating efficiency, and modular maintenance advantages.

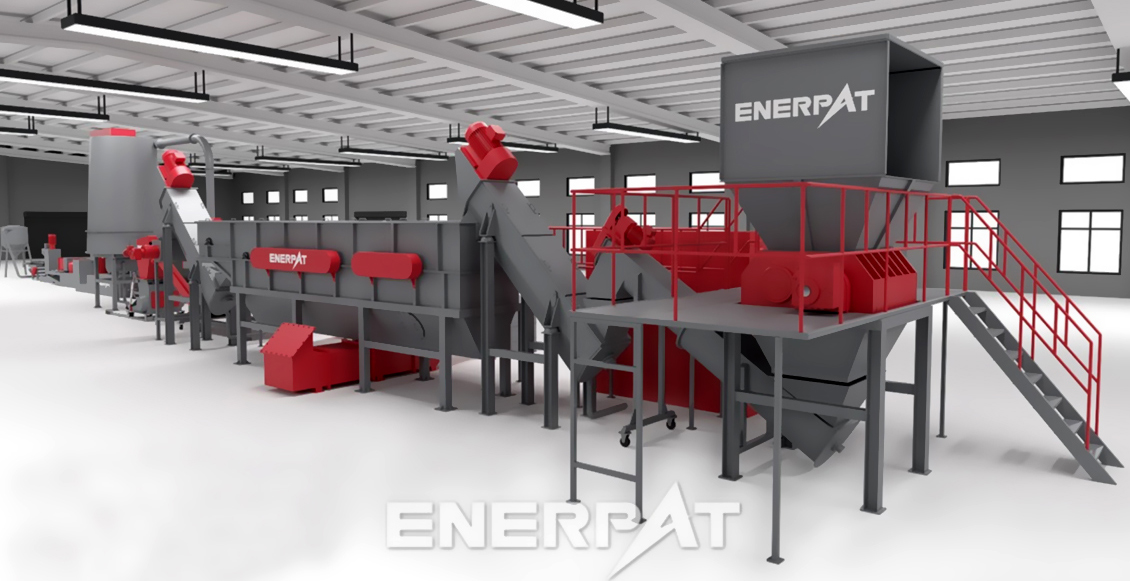

7. Why choose ENERPAT when purchasing steel shredders for sale?

In summary, if you’re in the market forsteel shredders for sale and want a reliable, high-performance solution, ENERPAT stands out for several reasons:

ENERPAT offers a wide range of shredders—fromMSA-F single shaft toMSB-E dual shaft toMSC-E four shaft models—covering low-volume to heavy-duty scrap metal shredding applications.

Their machines are built withhigh-strength, heat-treated alloy blades, modular housing, and robust gear systems designed for long life and reduced maintenance.

IntelligentPLC control systems, overload protection, and modular maintenance design make ENERPAT shredders easier to operate, safer, and more cost-effective over their lifecycle.

ENERPAT’s reputation as a globalScrap Steel Shredder Manufacturerand their provision of spare parts, technical support, and logistics services provide added confidence, especially for international buyers.

If you want to understand more deeply How to Choose the Right Steel Scrap Shredder Machine, or compare different shredder types and maintenance strategies, see our detailed guide here:How to Choose the Right Steel Scrap Shredder Machine.

8 Final takeaway

Buying asteel shredder for sale is not simply about finding the lowest price—it’s about selecting ascrap metal shredder machine that delivers reliable throughput, consistent shredding performance, efficient operation, and manageable maintenance over many years. By focusing on throughput, shredder type, build quality, control systems, operational costs, and supplier service, you’ll be better equipped to make a smart investment.

When performance, durability, and long-term support are priorities,ENERPAT Scrap Steel Shredder Manufacturer offers a portfolio of metal shredding solutions that are worth serious consideration. Whether you’re processing light scrap, bulky steel drums, automotive bodies, or mixed metal waste, ENERPAT’s shredders are built to deliver the high productivity and low downtime essential to modern recycling operations.

If you’re ready to explore high-performance steel shredders for sale, reach out to ENERPAT to discuss which shredder model aligns best with your scrap metal input stream, particle size goals, and operational workload.

About ENERPAT

ENERPAT is a global recycling and environmental protection equipment manufacturer with decades of experience in shredder design, scrap metal processing, and waste recycling. Their shredders are used worldwide in scrap yards, recycling centers, auto dismantlers, and industrial waste recovery systems.

WhatsApp:+86 177 6803 1176

E-mail: inquiry@enerpat.net

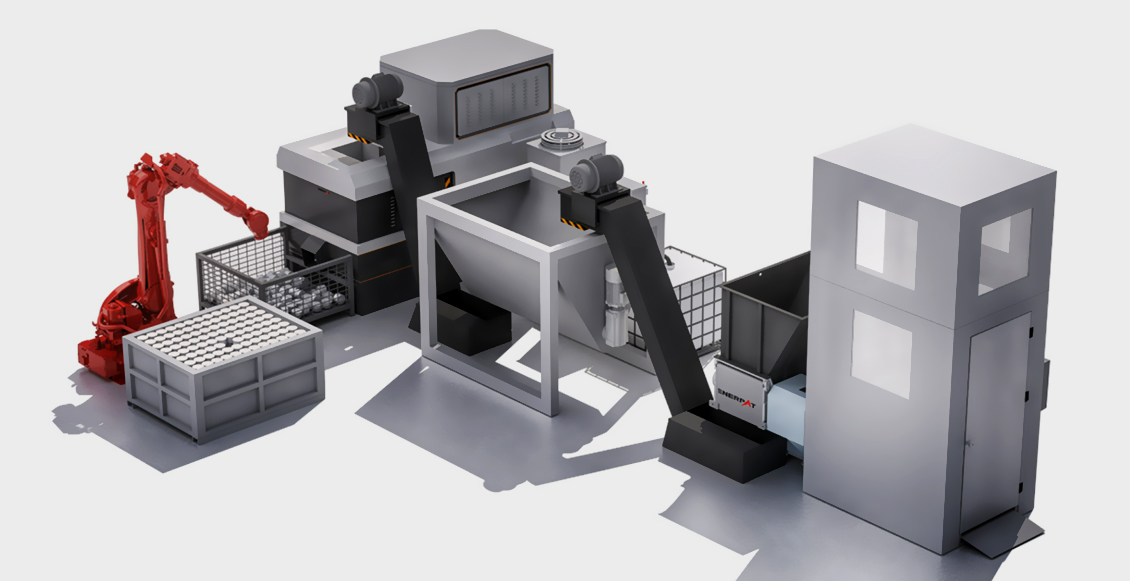

Oil Filters Recycling Line

Oil Filters Recycling Line

Pocket Coils Shredding and Sorting Solution

Pocket Coils Shredding and Sorting Solution

Disposal Solutions for Scrap Metal Chips

Disposal Solutions for Scrap Metal Chips

General Industrial Waste Recycling Solution

General Industrial Waste Recycling Solution

Bulky Waste Recycling System

Bulky Waste Recycling System

Home Appliances Shredding and Sorting Recycling Solution

Home Appliances Shredding and Sorting Recycling Solution

Plastic Film Washing and Pelletized Line

Plastic Film Washing and Pelletized Line

ACSR Recycling Solution

ACSR Recycling Solution

Cast Aluminum Shredding and Recycling Line

Cast Aluminum Shredding and Recycling Line

Lithium Ion Battery Recycling Plant

Lithium Ion Battery Recycling Plant

Solar Panel Recycling Equipment Line

Solar Panel Recycling Equipment Line

Aluminium Scrap Recycling Plant

Aluminium Scrap Recycling Plant

Single Shaft Shredder

Single Shaft Shredder Two Shafts Shredder

Two Shafts Shredder Four Shafts Shredder

Four Shafts Shredder Granulator

Granulator Hammer Mill

Hammer Mill Hydraulic Shredder

Hydraulic Shredder

Email:

Email:  Phone(Whats App):

Phone(Whats App): Add:

Add:

Whatsapp

Whatsapp